Tungsten karbidde gury ýer üçin zolaklar

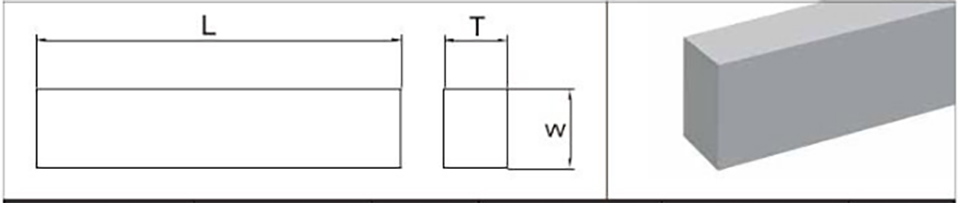

Beýany

Tegenen karbid tekiz barlary esasan wolfram karbide we poroşok metallurgiýa usullary bilen ýasalan wolfram karbide we koboram poroşokyndan ýasalýar. TOWWSTen karbiniň esasy öndürijiligi powerfik baýragy, top degirmeni, bogmak we günäkärlemekdir. Dürli ulanyş üçin WC-iň mazmuny we COGSTen karbid inedördül meýdanda birleşiň mazmuny birmeňzeş däl. Gaty zalymly gönümel policetgid bar, esasan, çal guýulan demir materiallary, gatylaşdyryjy demir, gat bişiriň we syr kesilen, üwemek, üzüm we çüýşeler bilen so zalymlykda ýa-da ussahanada hasam işlenip düzüler.

Amaly programmalar

1. Kömek üçin çydamly gurallar etmek üçin ulanylýar. Agaç işdeşi pudaky, plastmassa plastmassa plastmassa plastinkalary

2. Maşyn guralynyň demir ýoly, bankomat maşynyna garşy kazyýetiň garşysynda geçirilen garşydaşlyk platosy ýaly, bankomat maşynyna garşy garşy göreş platasy we ş.m.

3. Rezin we plastmassa pudagynda geýip, çydamly bölekleri ýasamak üçin ulanylýar.

4. Galyplary ýasamak üçin ulanylýar.

5. 5. Sements sementli otboid plitalaryny dürli maksatlar üçin material aýratynlyklary yzygiderli we sekak karbide planetleriň degişli maddasy däl.

Aýratynlyklary

Aşakdaky ýaly umumy ululyk:

| Galyňlygy | Ini | Uzynlygy | Galyňlygy | Ini | Uzynlygy | ||||

| mm | mm Çydamlylyk | mm | mm Çydamlylyk | + 1.5mm Çydamlylyk | mm | mm Çydamlylyk | mm | mm Çydamlylyk | + 1.5mm Çydamlylyk |

| 2 | + 0,3 / 0.1 | 3 | + 0.4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 15 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 4 | + 0.4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 16 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 5 | + 0.4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 18 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 6 | + 0.4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 20 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 8 | + 0.4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 22 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 10 | + 0.4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 25 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 12 | + 0.4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 28 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 14 | + 0.4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 31 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 15 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 5 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 16 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 6 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 18 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 8 | + 0.6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 19 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 10 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 3 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 12 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 4 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 13 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 5 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 15 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 6 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 16 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 8 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 18 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 9 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 20 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 10 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 22 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 11 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 25 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 12 | + 0.4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 30 | + 0.6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 13 | + 0.4 / + 0.2 | 310 | |||||

Üstünlikleri

"Tungsten" zergär zolagymyzyň artykmaçlyklary:

1. Iň ýokary ýylylyk durnuklylygy.

2. Ýokary temperaturada deformasiýa garşy.

3. Iftal ýylmaly ýüň urşuň garşylygy.

4. Ýokary termiki geçiriji.

5. Ajaýyp oksidiýa dolandyryş ukyby.

6. ýokary temperaturada güýçli anti-poslama.

7. Himiki däl gowy poslama garşylygy.

8. Ýokary geýýän aýratynlyk.

9. Uzyn ussatlyk arzuwy.

Bukjasy

Semented Karbid barlary bukjasy:

Soraglaryňyz bar bolsa, islän wagtyňyz bilen habarlaşmak üçin hoş geldiňiz!

Önüm enjamlary

Çygly üweýji

Guratmak

Basyň

TPA basyň

Ýarym metbugaty

Gark bolmak

Gaýtadan işleýän enjamlary

Burawlamak

Sim kesmek

Dik üweýji

Ähliumumy üweýji

Uçar üwemek

CNC Milling enjamy

Gözleg guraly

Gatylyk metr

Pubogeter

Kwadratiki element ölçeg

Kobolt magnit gurallary

Metalografiki mikroskop